Handheld 3D Scanning Used by Skanska for Rehabilitation of Longfellow Bridge in Boston

|

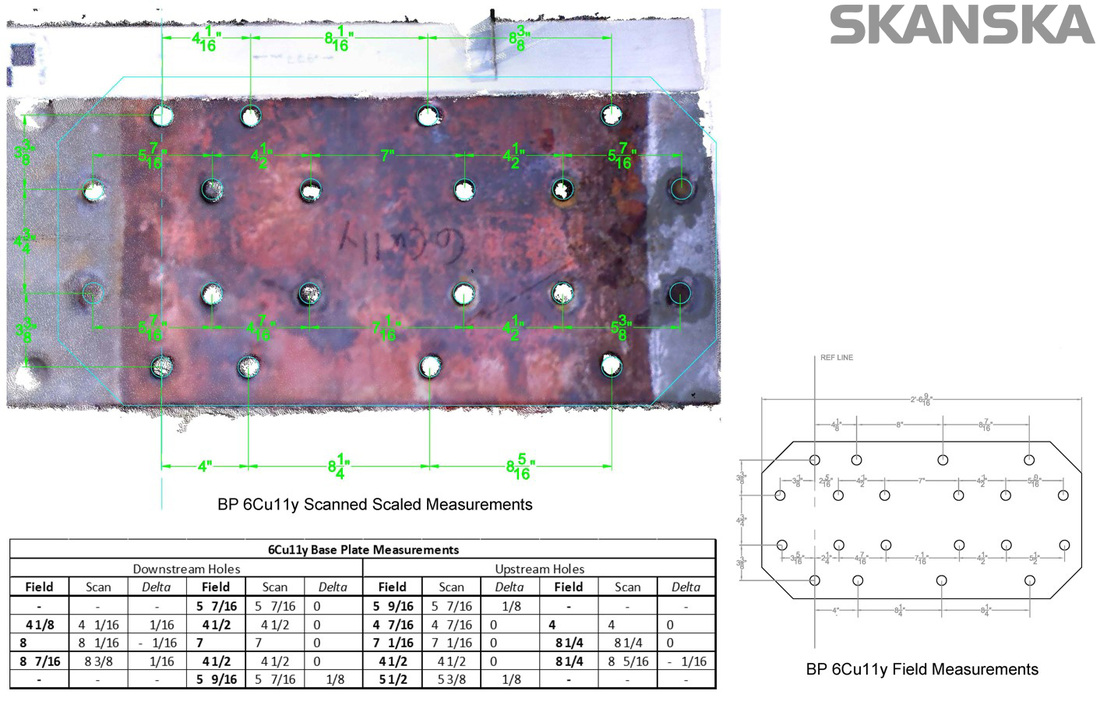

BOSTON, MA - Skanska is using the DotProduct handheld scanner to capture steel plate geometry for fabrication of replacement steel on the historic Longfellow Bridge. Early results indicate hand scanning is not only 10x faster than manual measurements, but also improves the quality of the replacement steel fabrication.

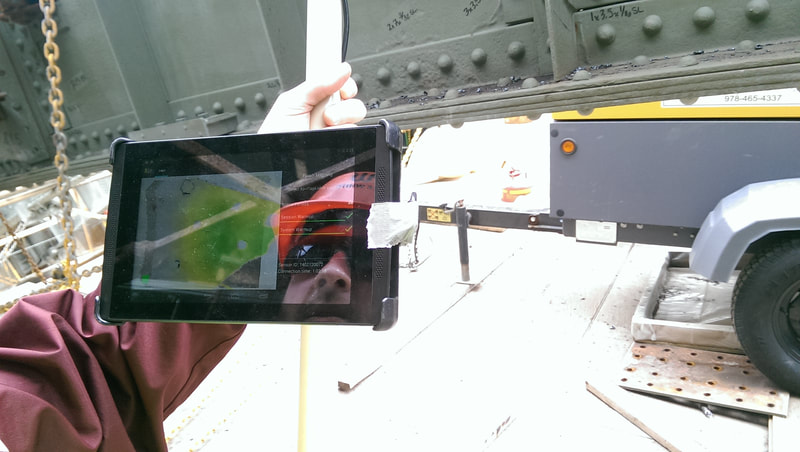

In 2012, Skanska was awarded a major design-build contract from the Massachusetts Department of Transportation for the extensive rehabilitation of the historic Longfellow Bridge from Boston to Cambridge. In this joint venture with J.F. White Contracting and Consigli Construction, they are addressing structural deficiencies, upgrading structural capacity, and bringing it up to modern code, all while maintaining the distinct historical architecture of the bridge. Once construction began in 2013, it was determined that 2600 baseplates were in need of replacement below each column of the 12-span bridge. Originally hot-riveted into place during the construction completed in 1906, each baseplate had a unique set of rivet holes that Skanska needed to measure accurately for production of the replacement plates. Initially, teams were sent in to climb the arches and pull hand measurements. However, Skanska quickly found this was time-consuming, potentially unsafe, and left room for human error. For every shipment of plates ordered, several were not fitting as planned. In need of a new, reliable solution for rapid and accurate measurement, Skanska turned to the DPI-SR Kit to document the baseplates. To avoid these challenges and inconsistencies, Skanska brought in the DPI-SR Kit. With the kit mounted to a range pole, each plate can be scanned in full 3D without any climbing or hand measurements. |

On the post-processing side, this also improved the overall workflow. Each scan file is now brought into Autodesk ReCap as a PTS file, where it is cropped and cleaned. From there, the data is saved as an RCS file which can be imported straight into AutoCAD.

Within AutoCAD, the Skanska drafting team is now able to measure distances and draw each new model directly on top of the color point cloud. On plates up to six feet, this is maintaining 1/16th inch accuracy, and avoiding the need for any measurement in the field.

When asked how this procedure compares to the field-measured alternative, Skanska Field Engineer Anna Greenfield explained, “The point cloud measurements are at least as accurate, and definitely more consistent.” The first shipment of baseplates ordered from the scan data proved the most accurate to date, showing immediate cost savings with the lowest number of returned plates. Skanska plans to continue DPI-SR use for the duration of the project, and are exploring other applications for the device on future projects. |

About Skanska USA Civil |

Skanska is one of the world's leading construction groups. In the U.S., we are a provider of comprehensive construction services and a developer of public-private partnerships. We apply our expertise to everything from small renovations to billion-dollar projects, using a variety of delivery methods.

|