Xtreme Outdoor Group specializes in building quality canopies, campers, and caravans for all makes of vehicles. Their team of investors, craftsmen, engineers, and designers pride themselves in ensuring that innovation, ergonomics, functionality, and style are all integral to each product designed. As part of an ongoing effort to further streamline and improve their custom design processes, Xtreme Outdoor recently partnered with their sister company KD Marine Design to implement Dot3D Pro handheld 3D scanning for reverse engineering, 3D measurement, custom fitting, and more.

After Xtreme Outdoor Group was established in 2018, the new team began to realize that the existing manufacturing processes were a bit outdated. They were still building canopies almost from scratch for each and every client. There were no standard 3D models being created or cataloged for canopies or pickup trucks. Under this system, even if they had already designed a canopy for a particular vehicle make/model/year, they would still have to start from scratch the next time they received a request for that same vehicle. All the manual tape measurements would have to be re-taken for the new vehicle, despite the fact that the resulting design work would most likely end up the same as the original.

After Xtreme Outdoor Group was established in 2018, the new team began to realize that the existing manufacturing processes were a bit outdated. They were still building canopies almost from scratch for each and every client. There were no standard 3D models being created or cataloged for canopies or pickup trucks. Under this system, even if they had already designed a canopy for a particular vehicle make/model/year, they would still have to start from scratch the next time they received a request for that same vehicle. All the manual tape measurements would have to be re-taken for the new vehicle, despite the fact that the resulting design work would most likely end up the same as the original.

The DotProduct DPI-10 handheld 3D scanning kit was deployed as a multi-faceted solution to alleviate some of these recognized inefficiencies. With the DPI-10, Xtreme Outdoor Group has now established an initiative to first 3D scan each vehicle upon arrival, informing the design while also populating a growing database of 3D reference models. They are now able to accurately reproduce canopies for multiple clients with the same vehicle, without having to start from scratch.

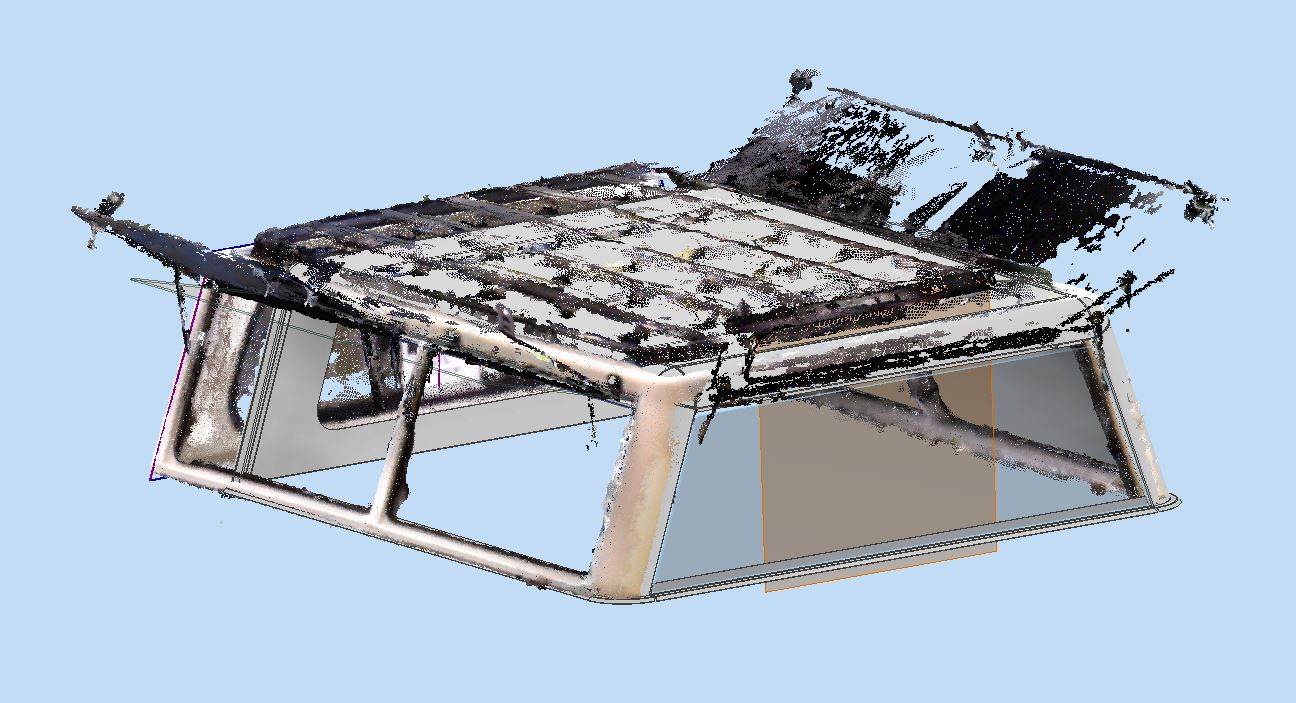

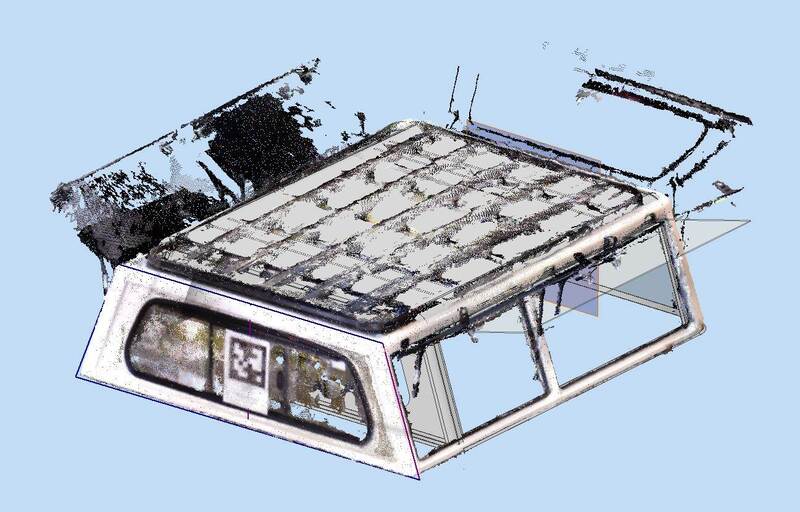

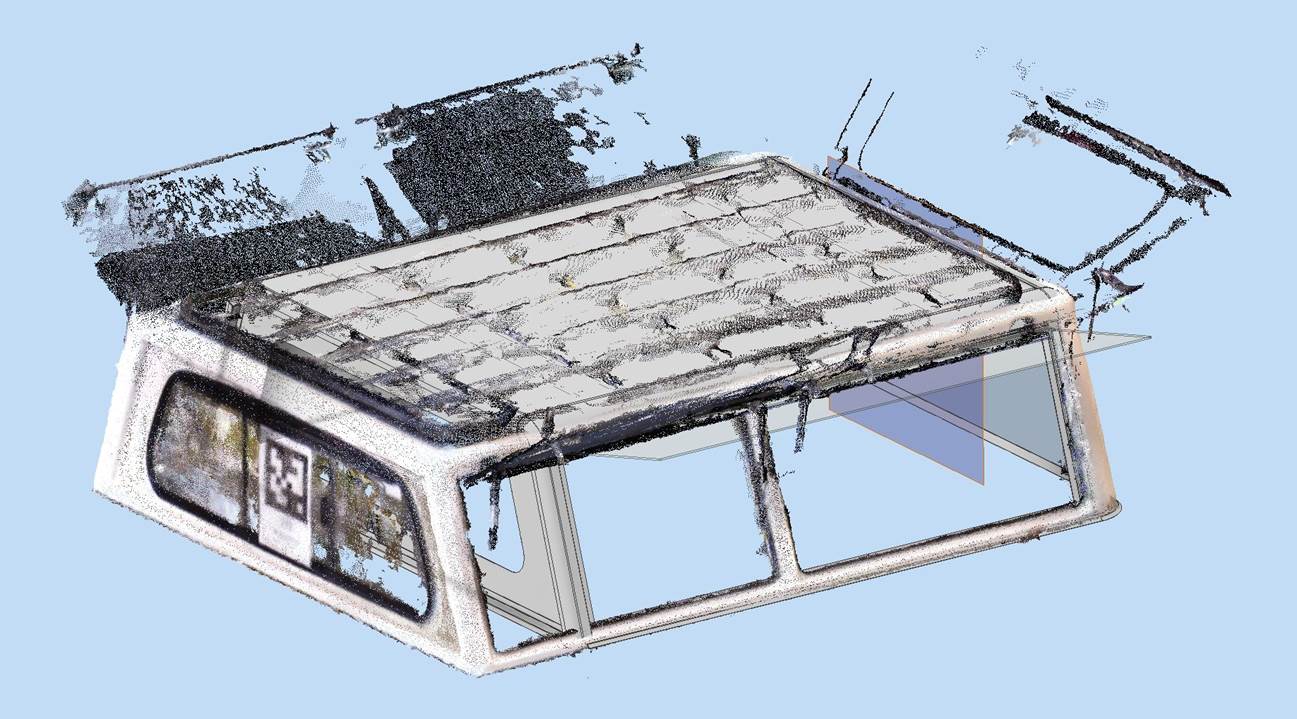

Secondly, they are now scanning all current canopies (as in the example below) and using these scans to create standard models for all the different pickup trucks for which they create canopies. The scan below was of a canopy produced for a Toyota Single Cab. In this case however, they were pressed to create a canopy model for a Toyota GD6 Double Cab (which requires a shorter version of the scanned canopy). With the existing 3D scan at their disposal, they not only designed a shortened canopy more effectively, but also used the opportunity to redesign the structure of the original canopy.

Secondly, they are now scanning all current canopies (as in the example below) and using these scans to create standard models for all the different pickup trucks for which they create canopies. The scan below was of a canopy produced for a Toyota Single Cab. In this case however, they were pressed to create a canopy model for a Toyota GD6 Double Cab (which requires a shorter version of the scanned canopy). With the existing 3D scan at their disposal, they not only designed a shortened canopy more effectively, but also used the opportunity to redesign the structure of the original canopy.

Both Xtreme Outdoor Group and KD Marine Design continue to expand their use of handheld 3D scanning across a growing range of 3D design and documentation applications. Please click below for more information on both companies: