3D Documentation & Retrofit of Offshore Oil Facilities in the North Sea with Step Change Engineering Limited

|

Headquartered in Aberdeen, Step Change Engineering Limited provides a powerful combination of integrated design, engineering and project management services for repair orders, minor modifications and small brownfield projects for oil and gas clients. They implement the most advanced and targeted technologies to deliver cost-effective, practical solutions for each project.

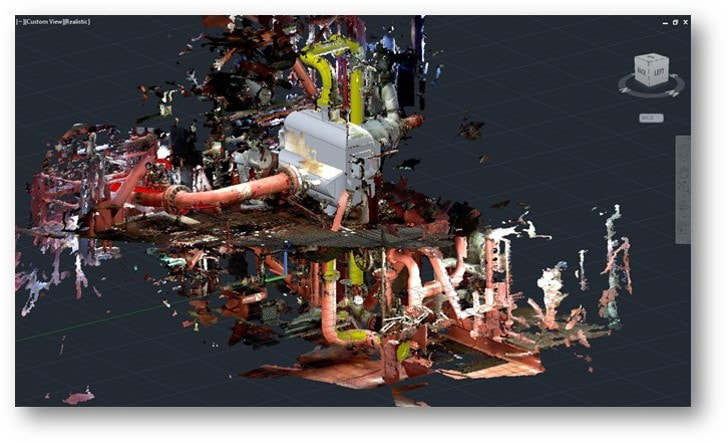

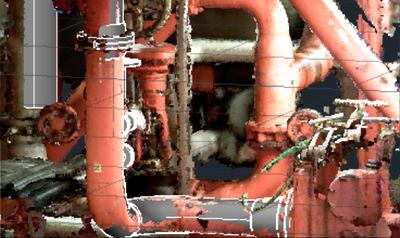

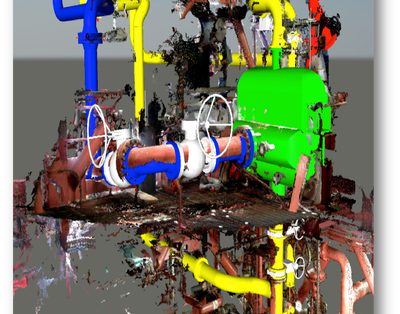

With a focus on technology that saves both time and cost, the DPI Kit was an obvious choice for Step Change Engineering to integrate into their offshore projects. In January 2015, Step Change was contracted for a concept project on an offshore facility in the North Sea. The task was to ensure the piping equipment and existing structures would be capable of a proposed modification, to be determined through 3D documentation, clash detection, and analysis of the existing installation. With offshore projects like this, operators find it both difficult and expensive to mobilize to the sites. The required work often needs to be completed during the shutdown period on the facility. Therefore, once approved for a visit, Step Change Engineering needed to maximize each minute on site and capture all the relevant data in a quick, reliable manner. With the Dot3D Pro and their DPI Kit, they were able to easily carry all required hardware in hand, and be fully set up and operational in a matter of only fifteen minutes. While a permit was required to use their DPI Kit on the facility, it was no more complex than the permit for a digital camera, so there were no issues getting approval. The area of interest was a very tight, complex space where other forms of 3D capture would have been more onerous in terms of time and cost. However, with the DPI Kit it took just three handheld scans to capture the required information. Using the ability to set the coordinate system and link scans in Dot3D Pro, Step Change Engineering was able to produce a complete 3D image in the field with just the three handheld scans. When asked what the alternative method would have been in this scenario, Neil Hebden, Corporate Design Manager for Step Change Engineering, explained the normal approach for concept |

studies such as these is to use digital cameras, visual inspection and existing drawings. Generally, the issue with that approach is the time taken and the difficulty to return to the asset should the proposed solution change.

By capturing with their DPI Kit, Step Change created a complete point cloud model of the scene in minutes, and left with confidence that they had captured everything they needed. Back in the office, they were able to bring the scans from Dot3D Pro through Autodesk ReCap and into the relevant AutoCAD files in less than 30 minutes. The ability to fill in gaps or adjust data in the field was also very important for ML&P. With their DPI Kit, ML&P can confidently produce complete color point clouds in single visits, only requiring photos and 360 videos as supplement.

One challenge was the dark nature of the vaults. However, with the attachment of a diffuse mounted light kit, the DPI Kit is able to capture excellent color data, even in complete darkness. After capture, the vault data passes directly into Autodesk ReCap, via the free plugin for DP import. Within ReCap, ML&P is able to crop, annotate, edit, and measure, all before also exporting to AutoCAD, Autodesk Utility Design, Infraworks, Navisworks, and other Autodesk programs. |

About Step Change Engineering LIMITED |

Step Change Engineering’s capabilities encompass a powerful combination of integrated design, engineering and project management services. Their services focus on smaller brownfield projects, modifications and repair orders, with a team of diverse expertise covering all engineering and project management disciplines.

|