Last month I traveled to Florida Marine Transportation’s (FMT) shipyard just outside of New Orleans. Ship Architect’s Josh Trippi arranged for us to visit a new 120 foot pushboat under construction so we could capture the grating geometry prior to installation of deck material. FMT has a contract to build five of these workboats and the goal is to make them all the same.

It was hot down in the belly of the boat; water was dripping everywhere and we endured a few dust clouds when some ventilation pumps started. My 30 year old Redwings which first served me on oil rigs in Oman and Abu Dhabi were just right to keep from slipping on the steel framework.

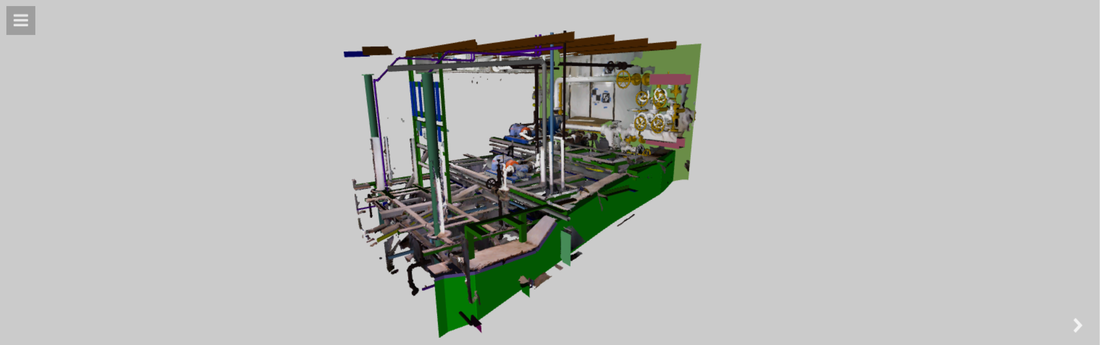

It took us about an hour to set up four survey targets and scan the area of interest. I used a Leica S910 disto to survey in the checkerboard target coordinates and then scanned the scene with our DPI-8X. The disto is a nice-to-have, not must-have but it does allow us to wring out scale and drift errors in the handheld data. We have a good workflow to use the control points we capture with the S910 or other disto’s as constraints in a post processing optimization step.

RSS Feed

RSS Feed