-The DotProduct Team-

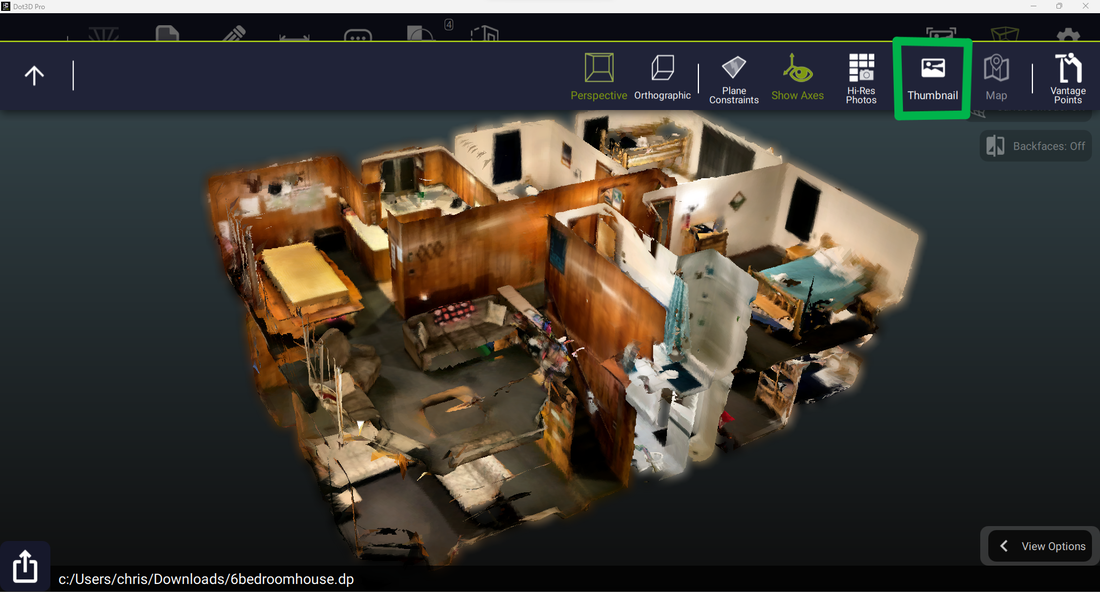

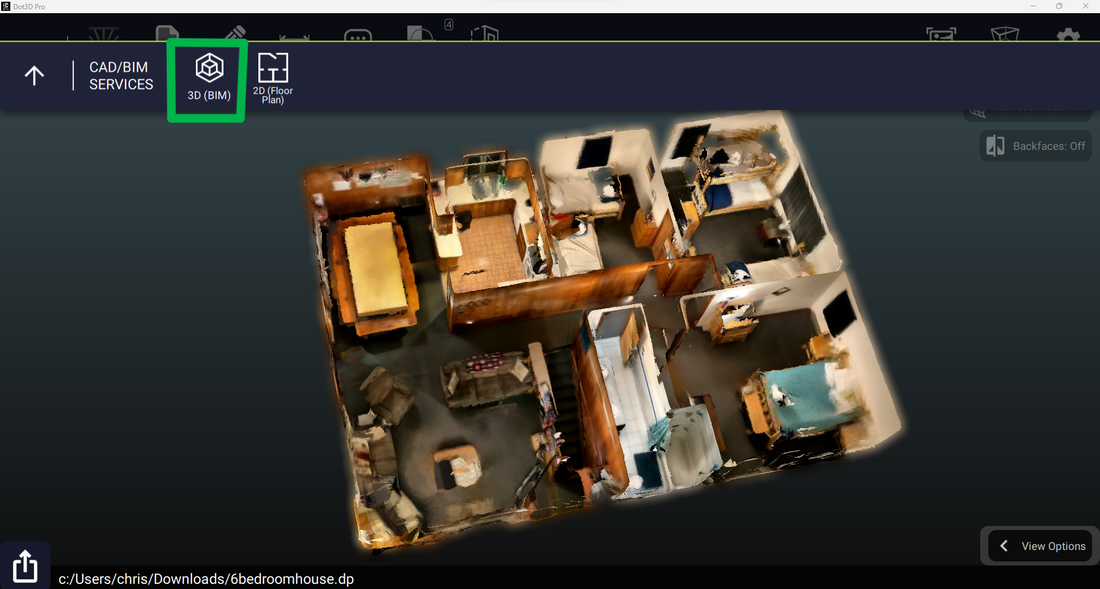

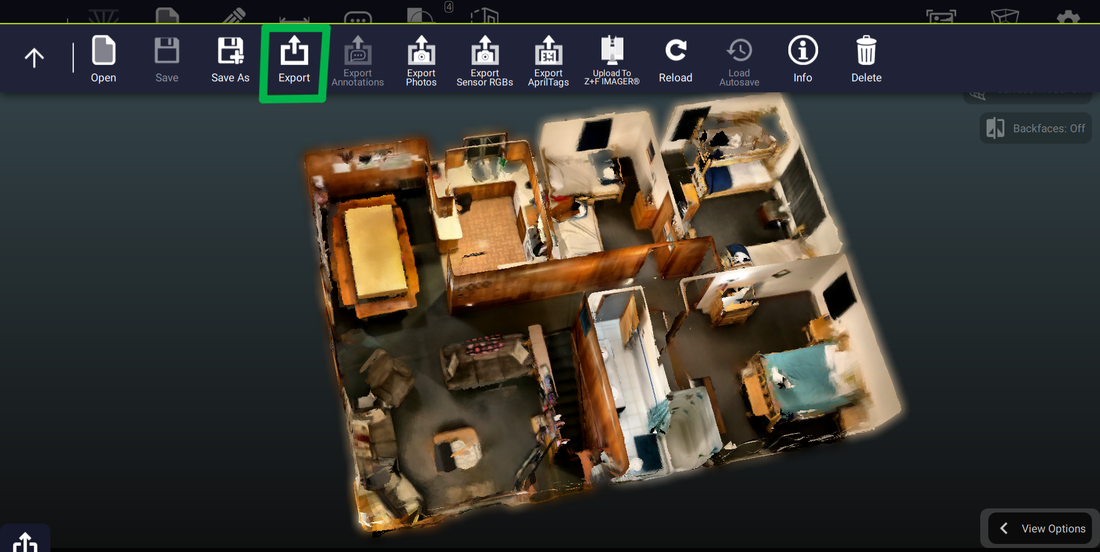

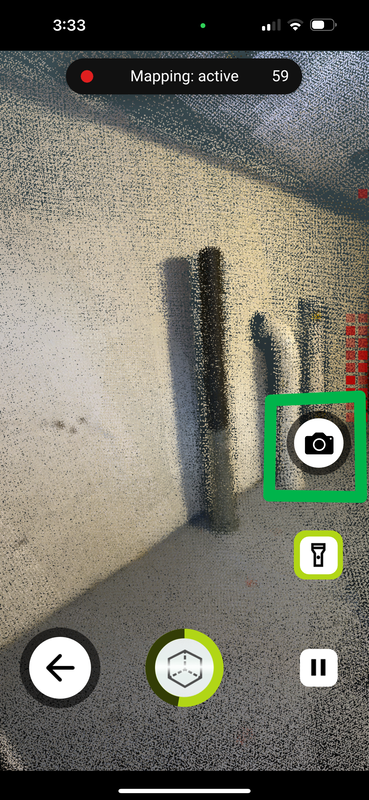

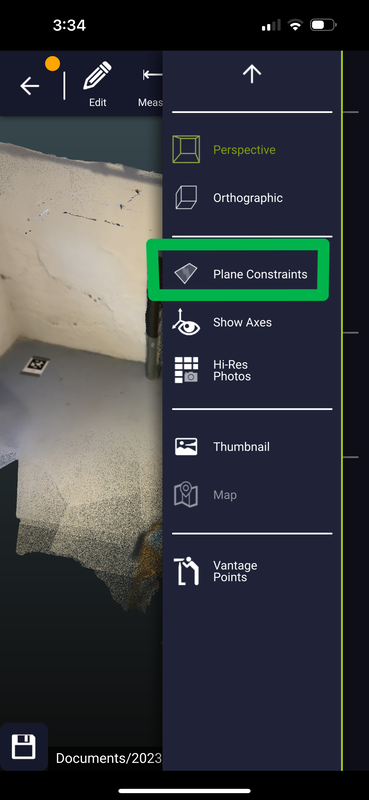

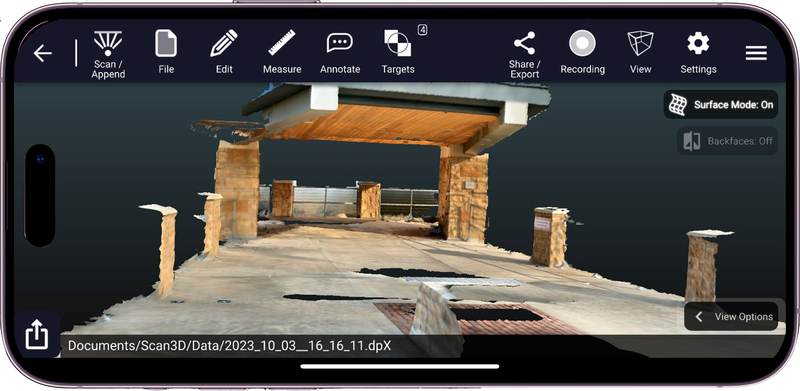

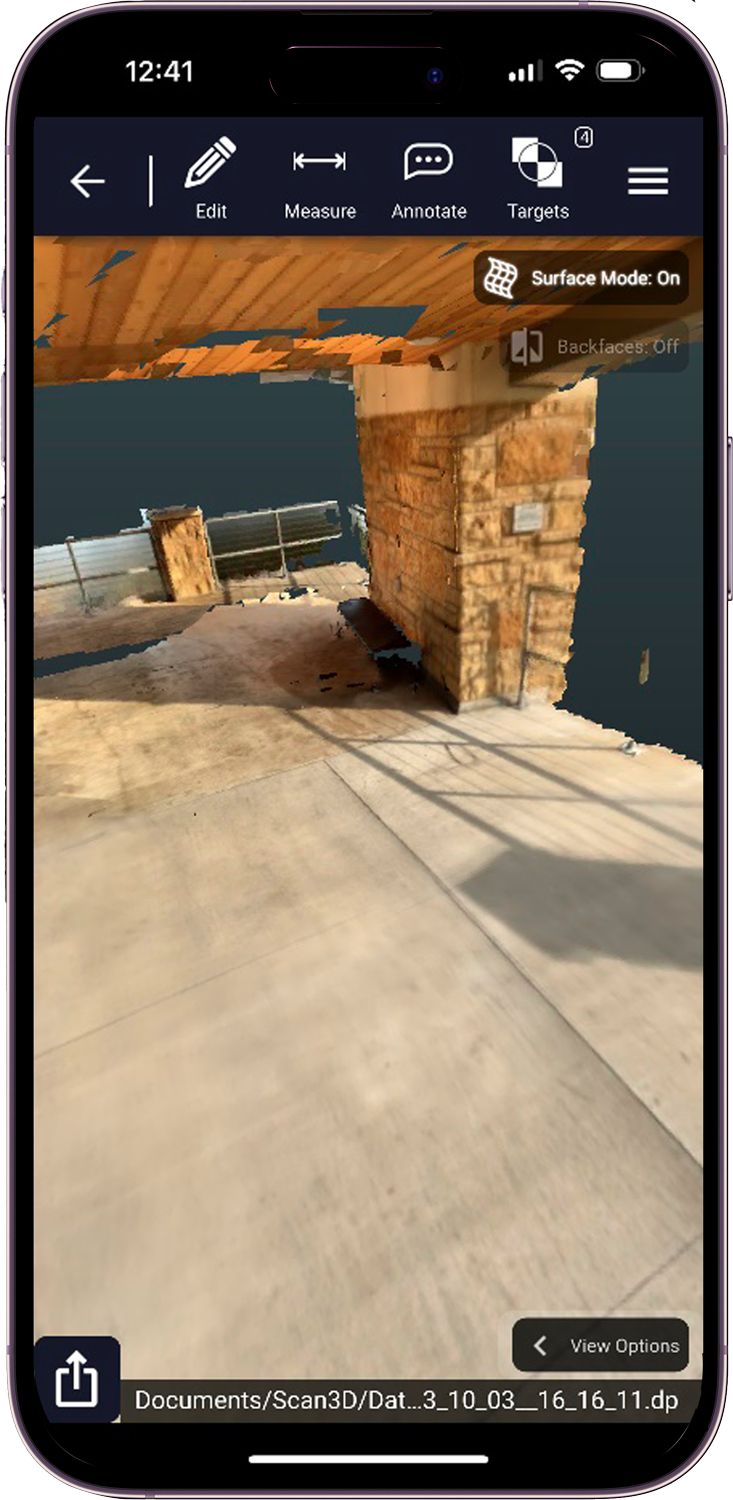

- Scanning an entire large condo inside and out with an iPhone 15 Pro

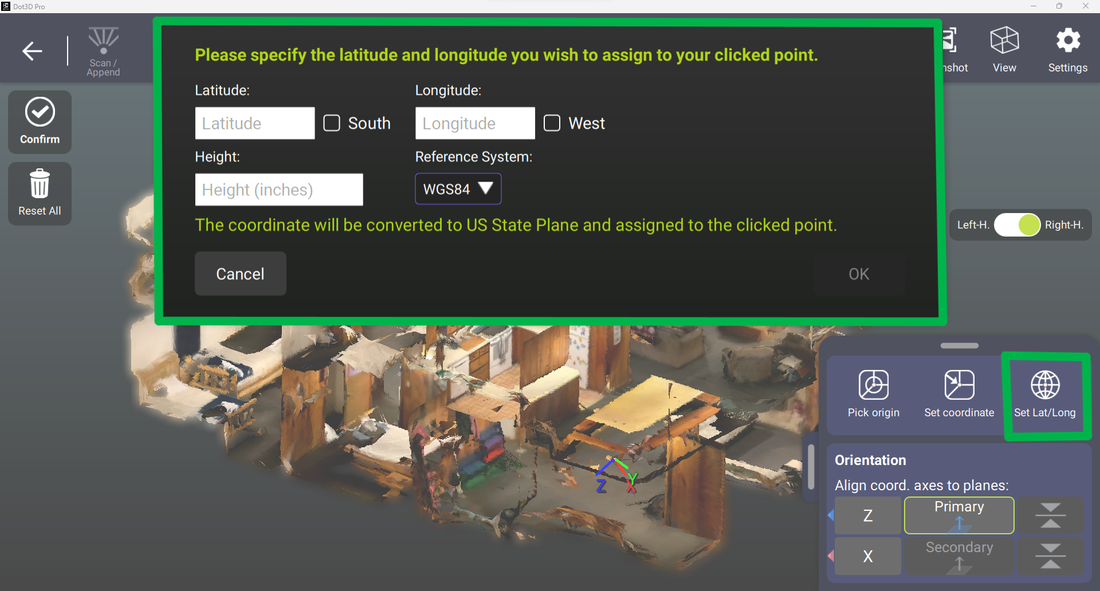

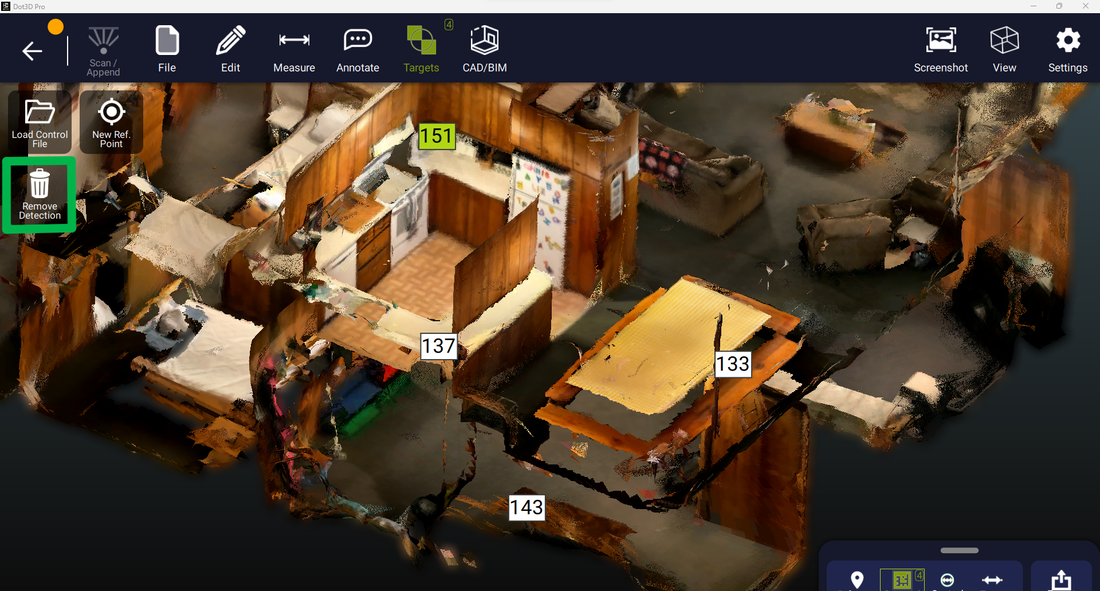

- Optimizing with the assistance of an extensive, accurate survey control target file (tied into geo-coordinates obtained outdoors)

- Analyzing the resulting accuracy compared to control (1/100 ft!)

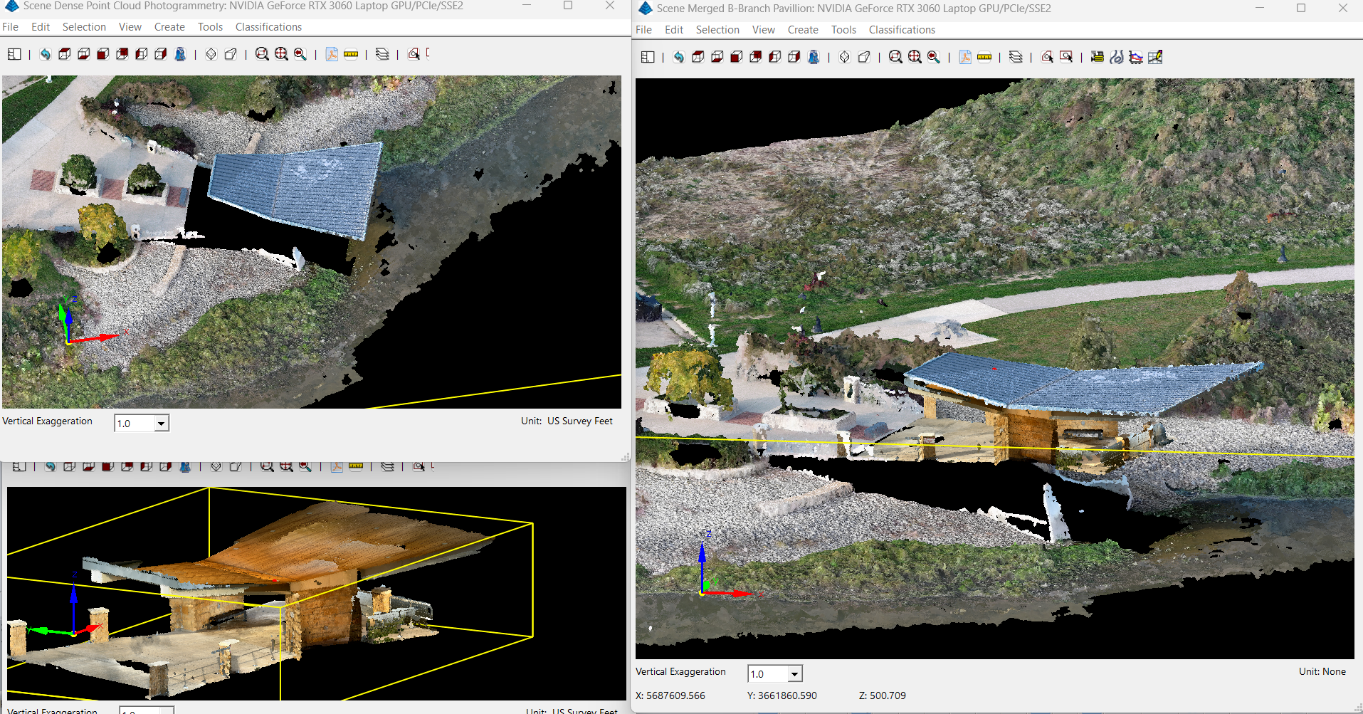

- Working with Dot3D Edit for convenient desktop scan editing

- Merging Dot3D data with drone data tied into the same control

1 Zebra ET85 Rugged Tablet

1 Intel RealSense Depth Camera D455f

1 iOgrapher Multi Pro Case

1 FoxFury RUGO Light Kit

...and of course, the very latest Dot3D Pro!

Follow along: Dot3D Feature Highlights (subscribe here!)

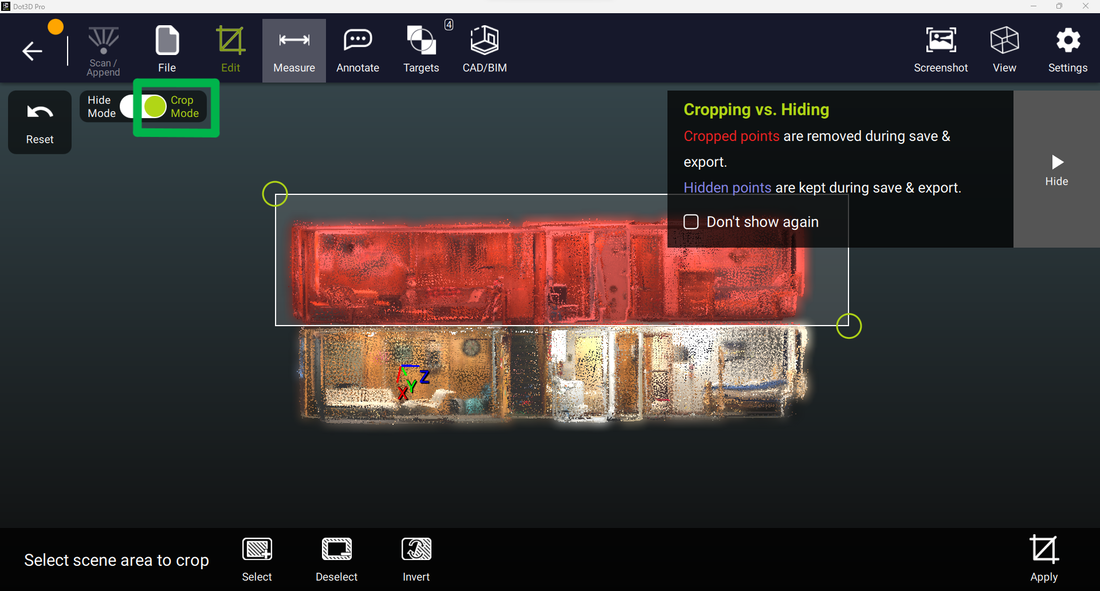

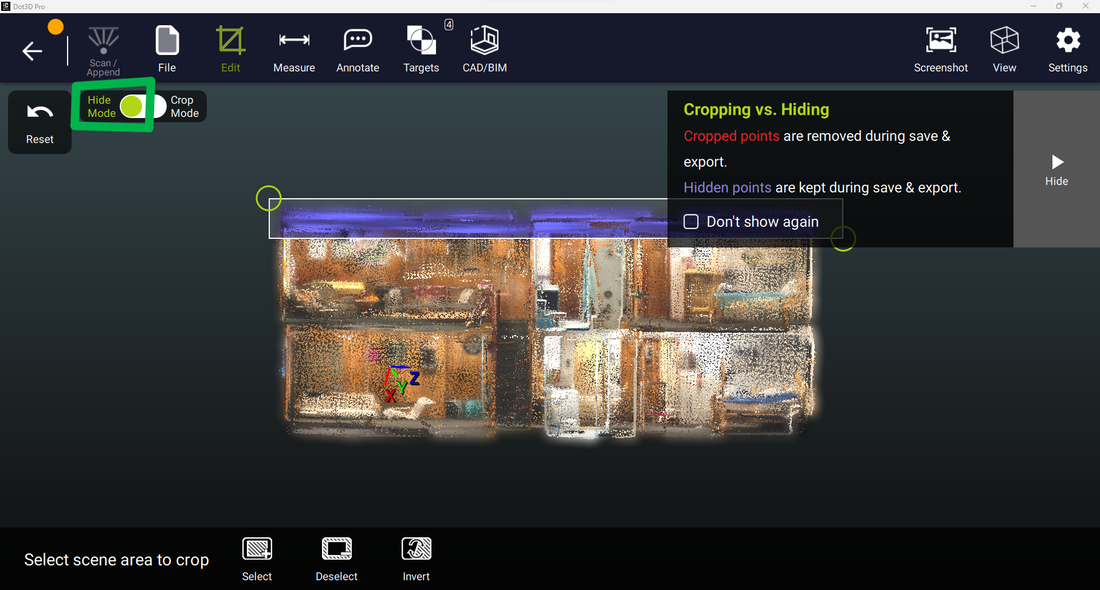

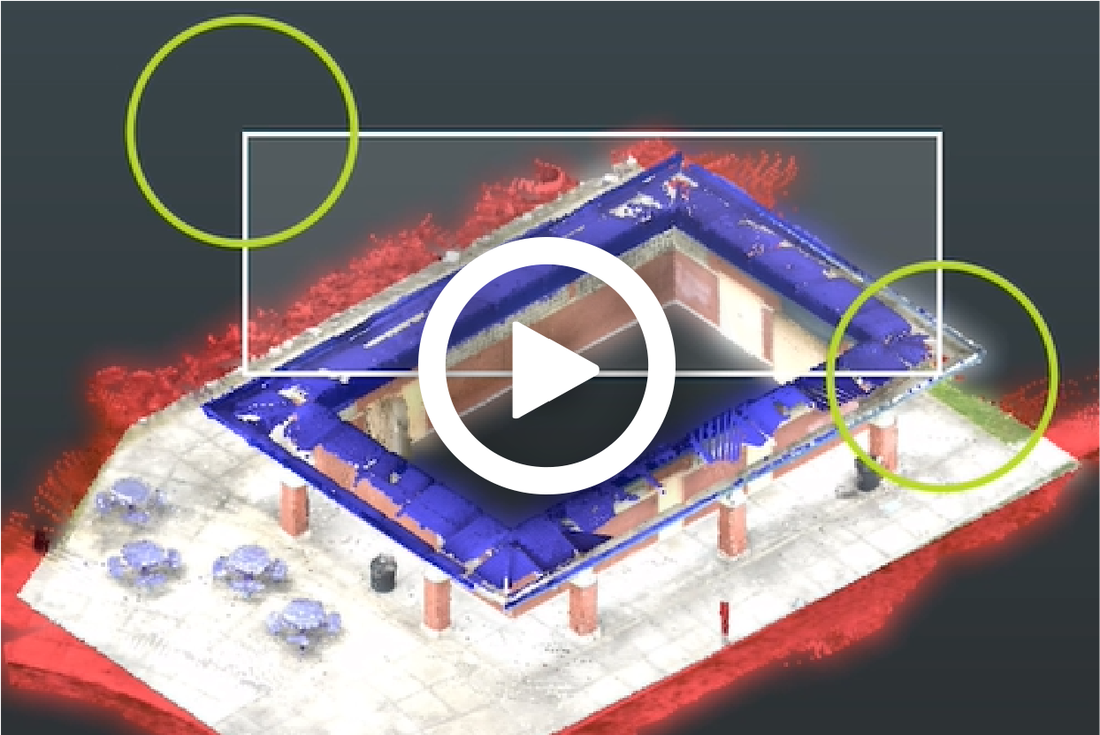

For today's latest highlight...Cropping & Hiding! Easily clean up your scans by selecting and deleting all the points you don't want with this convenient, multi-staged cropping tool. Or, if you prefer to retain all points but still hide some from view in Dot3D, you can take advantage of the new "Hide" option.

RSS Feed

RSS Feed