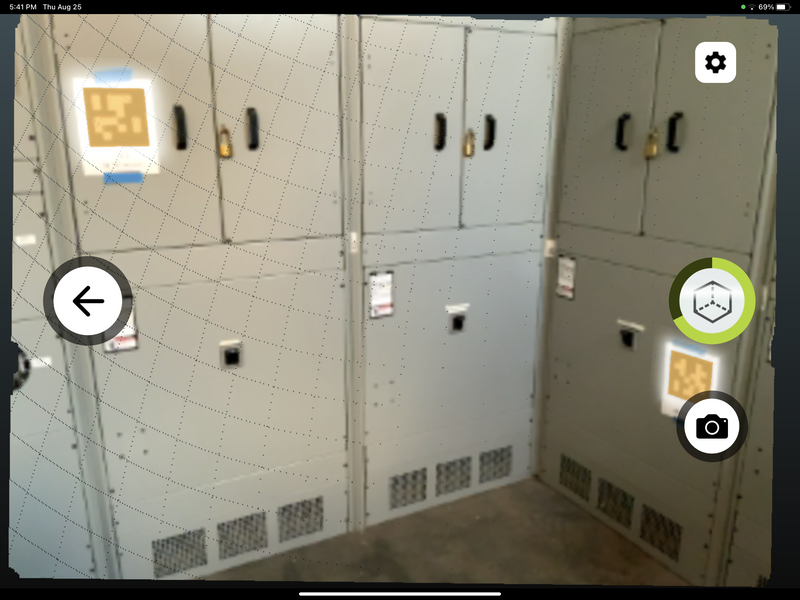

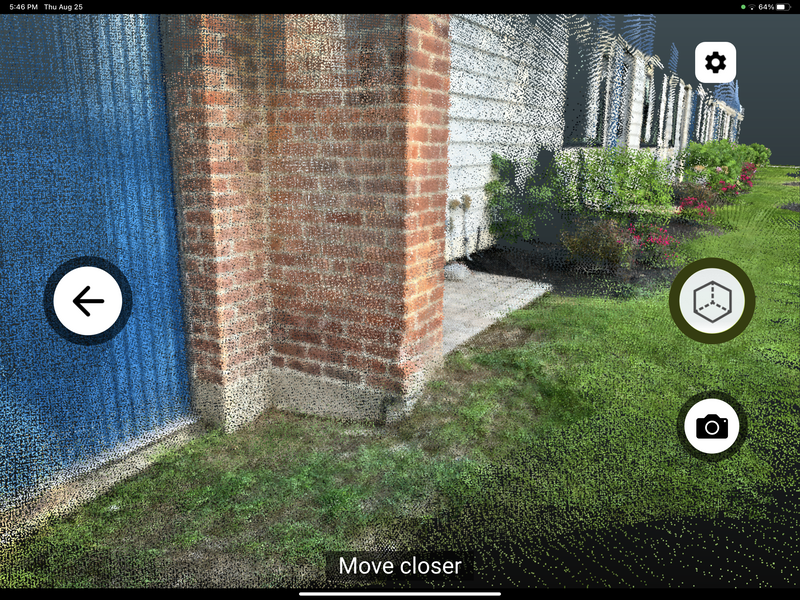

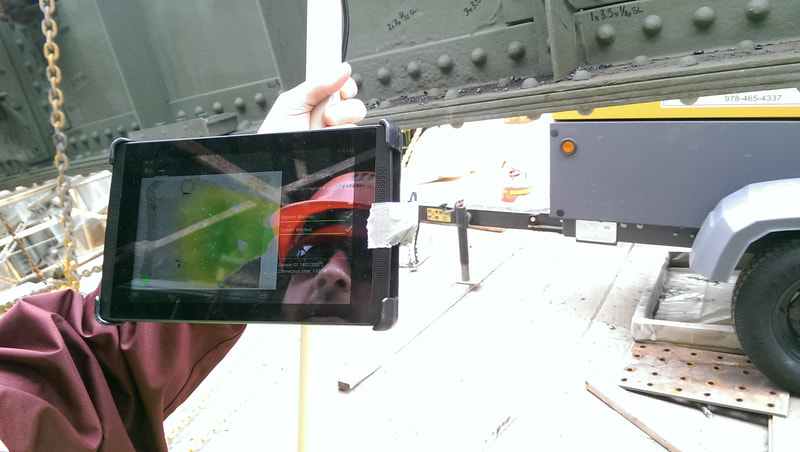

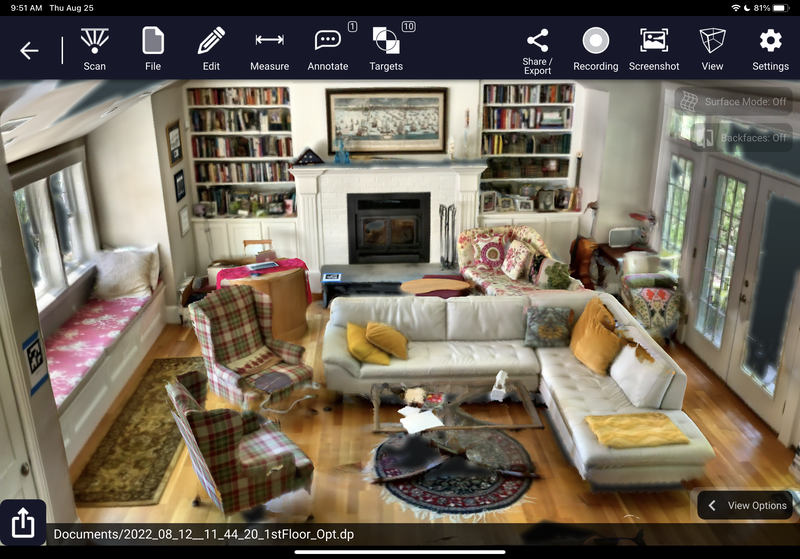

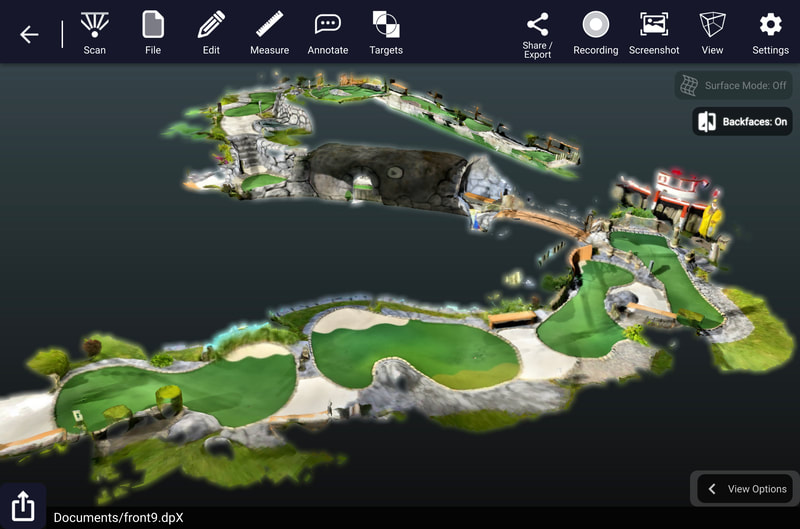

Stop by the booth for live demos of the latest Dot3D for iOS & more.

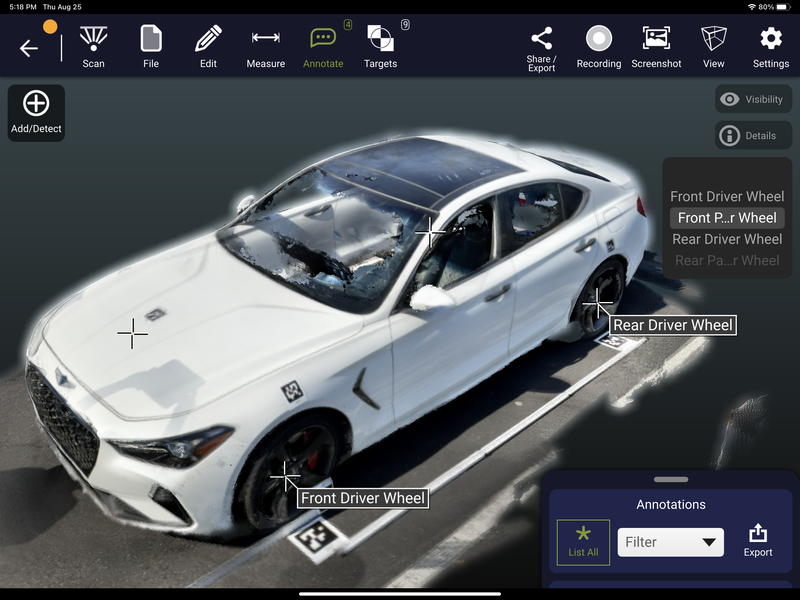

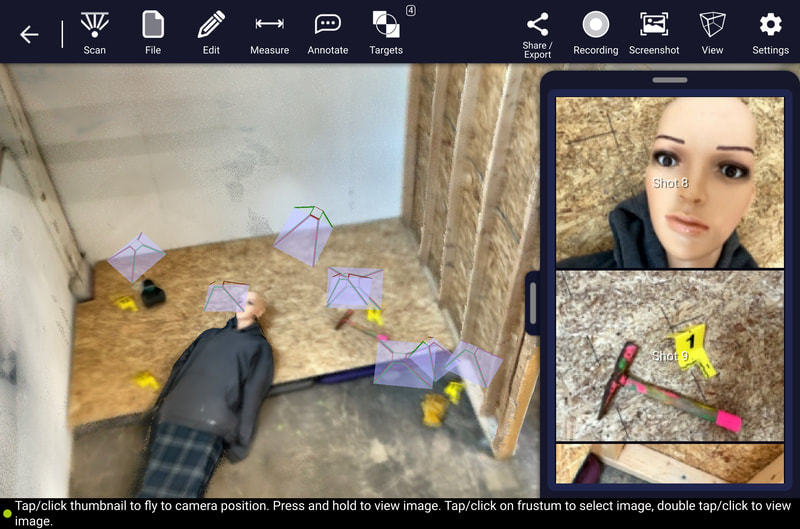

Don't forget to snap HD photos while scanning! Whether you're looking to add legibility on small equipment tags, document damages, photograph evidence, or just generally add much more 2D resolution from important viewpoints, this powerful capablity has benefits in almost every application for Dot3D.

RSS Feed

RSS Feed